Oil Management after HACCP standards – Part 2: Documentation

Share

Documentation is one major part of working after HACCP standards in commercial kitchens. Not only to keep your food quality and safety standards high, but also to get an overview about costs and monitor single procedures and your overall operation.

How the HACCP standard applies to frying oil in regards to documentation:

The right oil management is not only filtering your frying oil, measuring the temperature and quality or changing the oil at the right time, it also includes tracking and recording what was done to maintain the quality of it.

Especially as Owner or General Manager you will not be in the kitchen and supervise everything 24/7. Therefore, documentation is key- Maintains your kitchen team a HACCP list for your fryers you will be able to monitor all processes done.

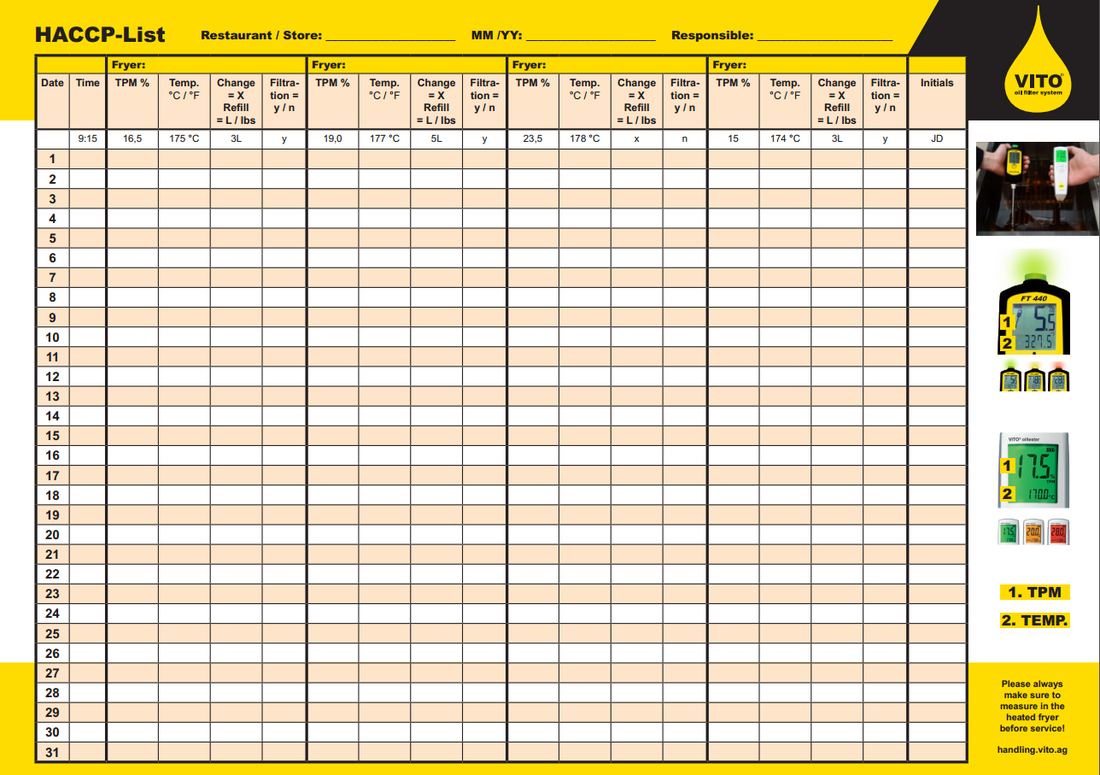

Here an optimal HACCP list for a commercial kitchen:

Benefits this list brings into your operation:

- Predated for a whole month

- Single sheets can be used for up to 4 deep fryers

- Easy to read

- Contains all necessary information (Oil quality, oil temperature, Information about filtration and oil changes/ how much oil was topped off)

In case a health inspector visits your location or a customer complaints about digestive issues after eating at your restaurant, this list is essential to show that the frying oil used is monitored and within regulations recommended by the authorities and therefore of good quality.

So, make sure to follow HACCP standards not only to manage critical points in your operation but also to get a perfect overview about your business.

Want to implement the shown HACCP list? Email us for a copy info@vitofryfilter.com