Frying habits every foodpro should know!

Share

Improve, adapt and save on frying oil

As food service managers know, it is very important to keep commercial fryers and the oil properly cleaned. The fryer maintenance includes everything from the oil or shortening selection itself, how/what you fry, what you do to maintain a high oil quality and the cleaning of the fryer.

Maintaining your restaurant fryer will extend the life of your oil and improve its quality which leads to a better taste of food and ensures your customers to keep coming back.

Adapt and improve - Your everyday care guide:

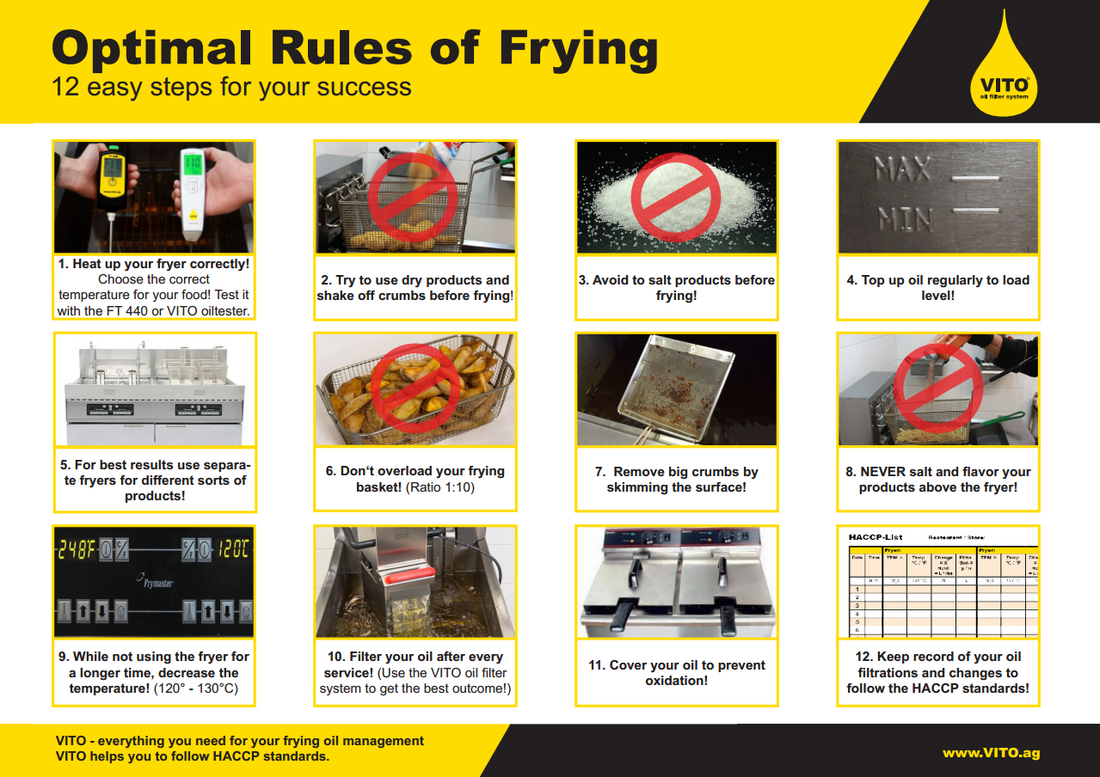

1. Slowly heat your oil to an optimal temperature around 350°F – Too fast heating and too high temperature will burn your oil, leading to reduced oil life & quality.

2. Keep your oil filled up between your fryer’s min & max level – fryers are built for a certain amount of oil, disregarding these levels will lead to too high or too low temperatures, directly affecting your food quality.

3. Avoid introducing unnecessary water to your fryers – by not salting prior to frying and shaking of ice crystals of frozen products, the oil life will be extended.

4. Do not overload your frying basket – if too much product is introduced at a time, your fryer will struggle to counter the temperature drop leading to soggy fried goods. Stay within a 1:10 ratio to your oil capacity in the fryer!

5. Introduce as little as necessary crumbs and particles to your oil – if filling up fryer baskets, avoid doing so above fryers, especially when filling directly from convenience products bags. Loose breading or broken fries end up in your oil, breaking it down faster.

6. Use dedicated fryers – if possible, try to use separate fryers for potato, meat, fish, etc. products. This avoids flavor transfer, can save on oil and makes it easier to react on special request from customers (allergies, dietary requests).

7. Keep your fryers clear of obvious contaminations – Using skimmers to remove floating particles throughout the day should be an automatism.

8. Do a microfiltration after every service – Removing finest particles, too small for your eyes to see, will tremendously increase oil life and food quality!

9. Reduce temperature and cover fryers while not in use – While your fryers are idle for an extended time, reduce the temperature to half and cover it. Heat and light harm the oil a lot and doing so will benefit the oil life greatly.

10. Change your oil at the right time! Use digital oil testers to determine the oil quality, they tell your team when it is time to exchange the oil. They measure the overall oil quality and are therefore the most reliable and accurate measurement devices for oil quality available.

11. Boil out your fryers – Maintaining a clean fryer is crucial! Removing burned in carbon from the fryer basin and thermostat leads to a higher oil life, more accurate temperatures, and an increased lifetime of your fryers. Use boil out tabs for an easy dosage and don’t forget to include your fryer

baskets to the soak.

12. Documentation is key to oversee that all guidelines were followed. Keep track of oil quality, filtrations done and oil changes.

Implementing those steps into your daily fryer operation routine are worth the effort. Reduced oil and labor cost due to less oil changes will greatly benefit your bottom line. It will also increase the quality of your fried dishes leading to a higher customer satisfaction.

Contact us to get a printable overview of the "Optimal Rules of Frying"